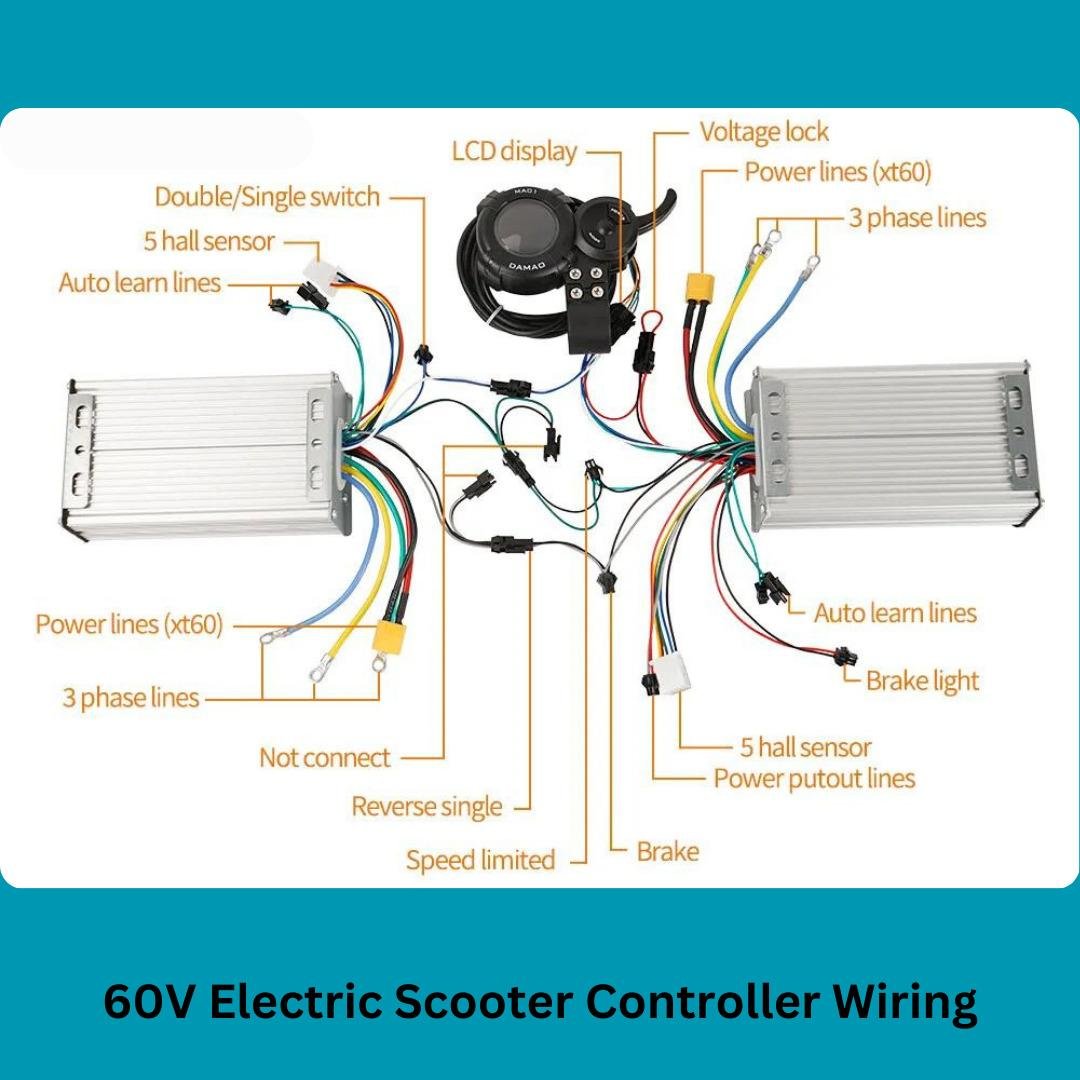

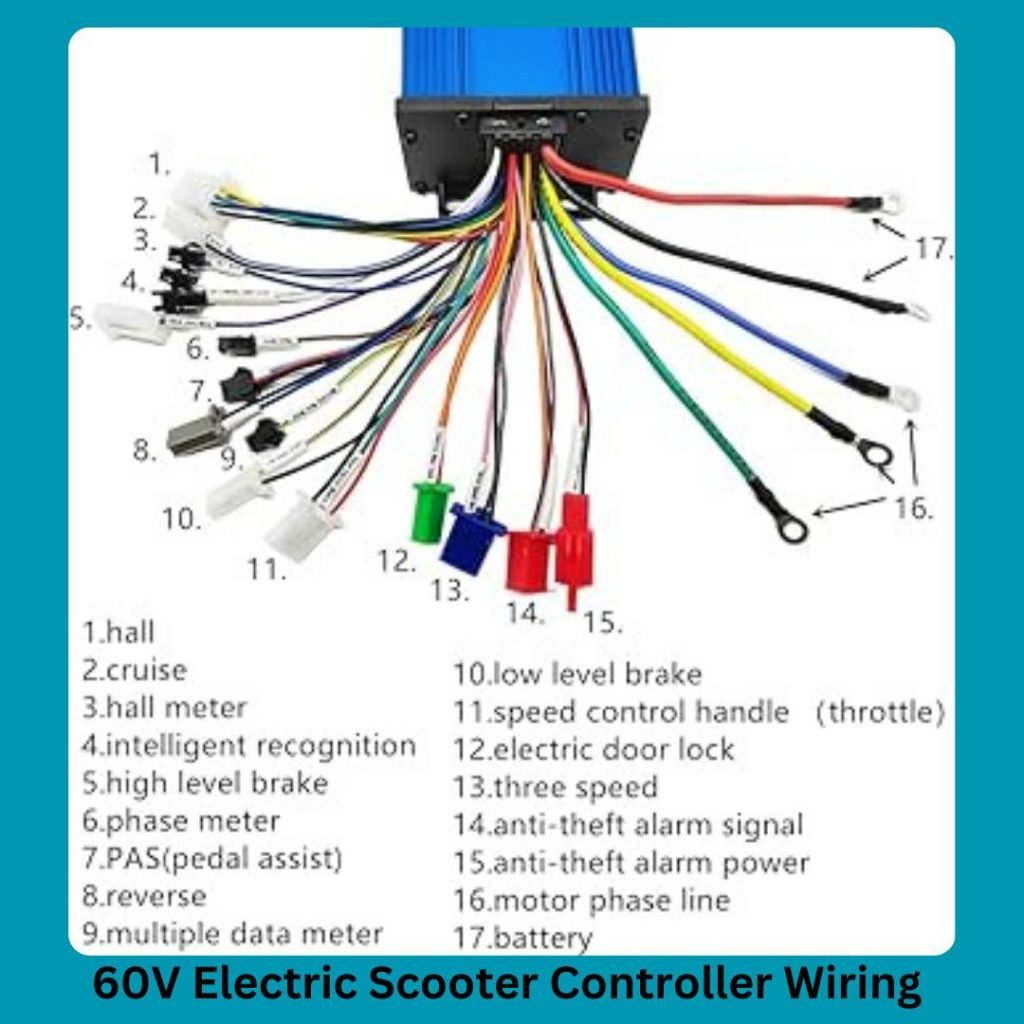

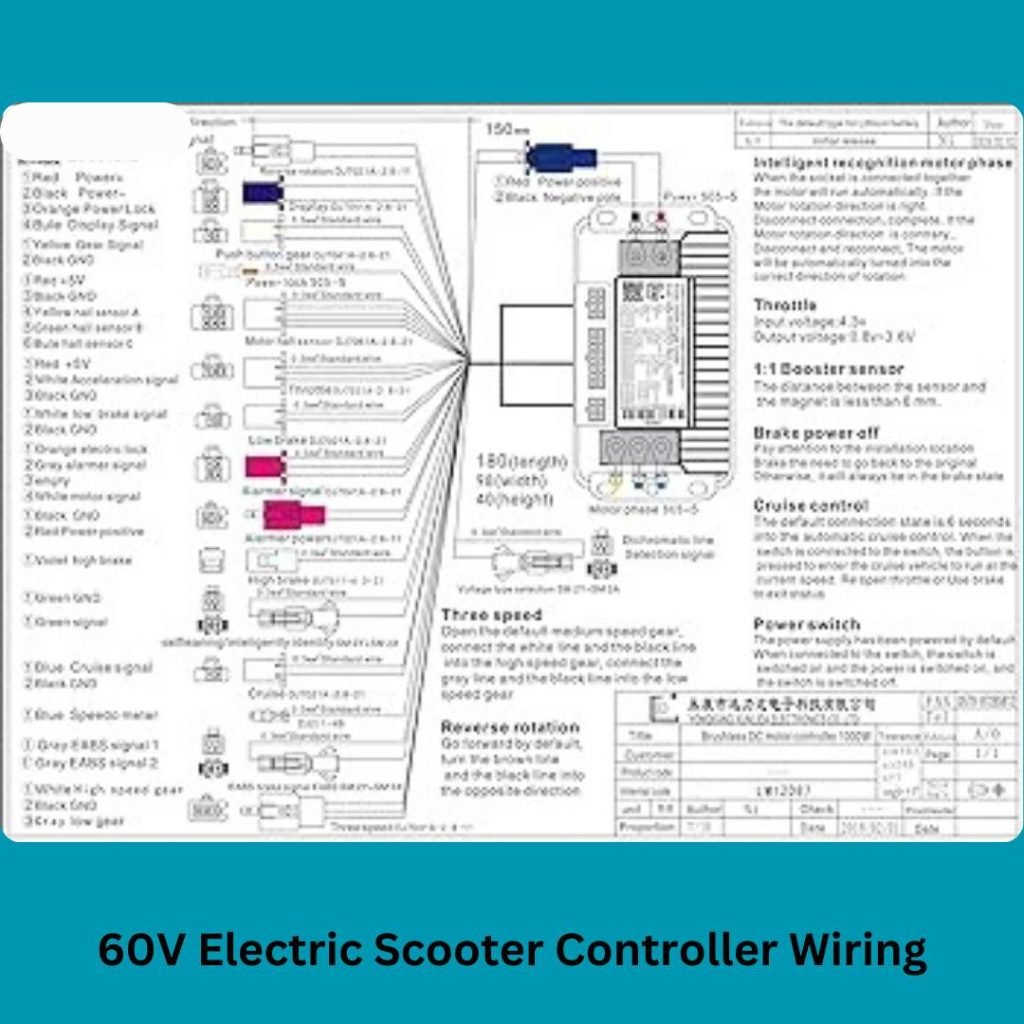

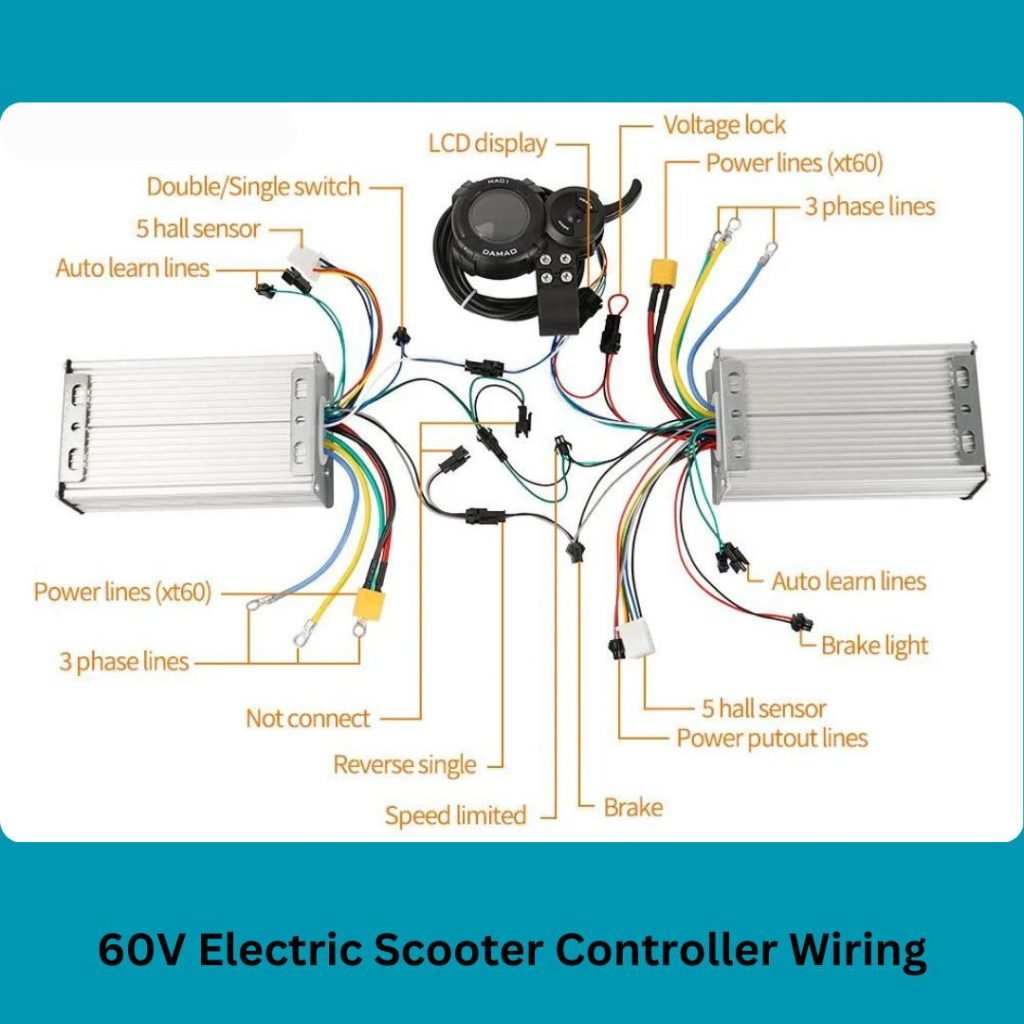

A 60V electric scooter controller wiring diagram details connections for power, motor, throttle, and brake systems. It ensures proper scooter functionality and safety.

Electric scooters have become a popular mode of transport due to their efficiency and eco-friendliness. Understanding the wiring diagram of a 60V electric scooter controller is crucial for maintenance and troubleshooting. The diagram includes connections for the battery, motor, throttle, and brake systems. Proper wiring ensures optimal performance and safety. Diagrams help users identify components and their connections, making repairs and upgrades easier. Familiarity with the wiring diagram can extend the scooter’s lifespan and improve its reliability. Always refer to the manufacturer’s guide for accurate information.

Introduction To 60v Electric Scooter Controllers

Electric scooters have become popular for urban commuting. The 60V electric scooter controller is a crucial part. This device helps in managing the scooter’s functions. It ensures smooth and safe rides.

The Role Of A Controller

A controller acts as the brain of the scooter. It manages power from the battery to the motor. This ensures optimal performance and safety. The controller also regulates speed and acceleration. It monitors the battery’s health and prevents overcharging.

Benefits Of 60v Systems

The 60V systems offer several advantages. They provide more power and faster speeds. These systems also offer better efficiency. This results in longer battery life. Enhanced power means smoother rides even on slopes. The 60V systems are ideal for heavy-duty use. They are perfect for longer commutes and tougher terrains.

Essential Components For Wiring

Understanding the wiring diagram for a 60V electric scooter controller is crucial. It ensures proper installation and optimal performance. Let’s dive into the essential components required for wiring.

Understanding The Circuit Board

The circuit board is the heart of the controller. It manages power distribution and controls the scooter’s functions. It contains various electronic components that ensure smooth operation.

Here are some key parts of the circuit board:

- Microcontroller: Acts as the brain of the system.

- Capacitors: Store and release electrical energy.

- Resistors: Control the flow of electrical current.

- Transistors: Amplify or switch electronic signals.

Key Connectors And Cables

Connectors and cables link the controller to various scooter parts. They ensure efficient communication and power transmission.

Important connectors include:

- Battery Connector: Links the battery to the controller.

- Motor Connector: Connects the motor to the controller.

- Throttle Connector: Connects the throttle to the controller.

- Brake Connector: Links the brakes to the controller.

Essential cables include:

- Power Cables: Carry electricity from the battery to the controller.

- Signal Cables: Transmit signals between the throttle, brake, and controller.

Understanding these components is key to wiring your 60V electric scooter controller properly.

Safety Precautions And Best Practices

Working with a 60V electric scooter controller wiring diagram demands caution. Safety precautions and best practices help prevent accidents and ensure smooth operation. This section covers key guidelines to follow.

Handling Electrical Components

Always wear protective gloves and goggles when working with electrical parts. These protect against electric shocks and injuries.

- Turn off the scooter and disconnect the battery.

- Use insulated tools to handle wires and connectors.

- Avoid working in wet or damp conditions.

- Double-check connections for tightness and accuracy.

Preventing Short Circuits

Short circuits can cause severe damage to your scooter. They may also pose safety risks.

- Inspect wires for any wear or tear.

- Ensure all connections are secure and properly insulated.

- Use a multimeter to test for continuity and proper voltage levels.

- Keep wires organized and separate to avoid contact.

Here is a quick reference table for safety checks:

| Task | Action | Frequency |

|---|---|---|

| Inspect Wires | Check for wear and tear | Weekly |

| Check Connections | Ensure tight and accurate connections | Every Use |

| Use Multimeter | Test for continuity and voltage | Monthly |

| Organize Wires | Keep wires separate | Every Use |

Step-by-step Wiring Instructions

Wiring the controller of a 60V electric scooter can seem hard. But, with clear steps, it’s easy. This guide will help you wire your scooter’s controller. Follow the steps below for a smooth process.

Preparing The Workspace

Before starting, prepare your workspace. Make sure it’s clean and well-lit. Gather all needed tools and materials.

- 60V Electric Scooter Controller

- Wiring Diagram

- Screwdrivers

- Wire Strippers

- Multimeter

- Electrical Tape

Use a table to keep tools organized. Lay out the wiring diagram for reference.

Connecting The Controller

Now, connect the controller. Follow these steps:

- Identify the Wires: Use the wiring diagram to identify wires. Common wires include throttle, brake, and motor wires.

- Strip the Wires: Use wire strippers to remove the insulation. Expose enough wire to make a good connection.

- Connect the Throttle Wires: Match the throttle wires from the controller and scooter. Twist them together and secure with electrical tape.

- Connect the Brake Wires: Repeat the process for the brake wires. Ensure a tight and secure connection.

- Connect the Motor Wires: Attach the motor wires to the controller. Use the wiring diagram to match the colors.

- Check Connections: Use a multimeter to check connections. Ensure there are no shorts or loose wires.

- Secure Everything: Use electrical tape to secure all connections. Make sure no wires are exposed.

Once all wires are connected, your scooter is ready to go!

Troubleshooting Common Issues

Understanding how to troubleshoot common issues with a 60V Electric Scooter Controller Wiring Diagram is crucial. This guide will help you identify and resolve common wiring problems and power fluctuations. Follow these steps to ensure your scooter runs smoothly.

Identifying Wiring Problems

Wiring problems can cause your scooter to stop working. To identify wiring problems, follow these steps:

- Check all connections for loose or frayed wires.

- Use a multimeter to test for continuity in the wires.

- Inspect the connectors for corrosion or damage.

If you find any damaged wires, replace them immediately. Make sure all connections are secure. Tighten any loose connectors to ensure proper contact.

Resolving Power Fluctuations

Power fluctuations can affect your scooter’s performance. To resolve power fluctuations, follow these steps:

- Check the battery voltage using a voltmeter.

- Ensure the battery is fully charged.

- Inspect the controller for overheating signs.

If the battery voltage is low, charge it fully. If the controller is overheating, check for proper ventilation. You might need to replace the controller if the problem persists.

Below is a table summarizing the common issues and their solutions:

| Issue | Solution |

|---|---|

| Loose or frayed wires | Check and replace damaged wires |

| Corroded connectors | Clean or replace connectors |

| Low battery voltage | Charge the battery fully |

| Controller overheating | Ensure proper ventilation |

Performance Testing And Calibration

Understanding the 60V Electric Scooter Controller Wiring Diagram is essential. This ensures the scooter runs smoothly and efficiently. The performance testing and calibration phase is crucial. It helps in verifying that all components are working as intended.

Ensuring Smooth Operation

To ensure smooth operation, inspect all connections. Check for any loose or disconnected wires. A loose wire can cause operational issues. Verify that the battery is properly connected. This is vital for the scooter’s performance.

Follow these steps to ensure smooth operation:

- Check the battery connection

- Inspect the motor wiring

- Ensure the controller is securely mounted

Adjusting Settings For Optimal Use

Proper calibration is key to optimal performance. Adjust the controller settings carefully. This ensures the scooter runs efficiently and safely. Refer to the manufacturer’s manual for specific instructions.

Use the following table as a guide:

| Setting | Recommended Value | Notes |

|---|---|---|

| Throttle Sensitivity | Medium | Ensures smooth acceleration |

| Brake Response | High | For quick stopping |

| Max Speed | 25 mph | Safe for urban use |

Electric Scooter Mirrors: Enhance Your Ride Safety!

Follow these steps for calibration:

- Set throttle sensitivity to medium

- Adjust brake response to high

- Limit max speed to 25 mph

Ensure each setting is tested thoroughly. This guarantees the scooter operates at its best.

Maintenance And Longevity

Ensuring the longevity of your 60V electric scooter involves regular maintenance. Proper upkeep can extend the life of your scooter’s controller wiring diagram. Routine checks and component upgrades play a significant role.

Routine Checks And Balancing

Regular inspections are crucial for maintaining your 60V electric scooter. Check the controller wiring diagram weekly.

- Inspect all wiring connections for wear and tear.

- Ensure no wires are loose or frayed.

- Verify the battery connections are secure and clean.

Balancing the electrical load is equally important. Uneven load distribution can cause failures.

- Check the voltage levels to ensure they are balanced.

- Use a multimeter to measure current flow.

- Adjust connections to distribute load evenly.

Upgrading Controller Components

Upgrading components can improve performance and durability. Start by identifying worn-out parts.

| Component | Upgrade Option |

|---|---|

| Wiring | Use higher-grade wires for durability. |

| Connectors | Replace with gold-plated connectors. |

| Controller Unit | Upgrade to a newer model for better performance. |

Replacing the controller unit can also enhance performance. Ensure the new unit is compatible with your scooter.

Following these steps can significantly extend the life of your scooter. Regular checks and timely upgrades make a big difference.

Frequently Asked Questions

How Do I Test My Electric Scooter Controller With A Multimeter?

To test your electric scooter controller, set your multimeter to DC voltage. Connect the probes to the controller’s power input. Check for correct voltage levels.

How Does A Scooter Motor Controller Work?

A scooter motor controller regulates the power from the battery to the motor. It adjusts speed and torque based on throttle input. This ensures smooth and efficient operation.

How Fast Does A 60v Electric Scooter Go?

A 60V electric scooter can reach speeds of up to 40-50 mph, depending on the model and rider weight.

How Do You Change The Controller On An Electric Scooter?

To change the controller on an electric scooter, first disconnect the battery. Remove the old controller. Install the new controller, reconnect the wires, and secure it. Test the scooter to ensure proper functioning.

What Is A 60v Electric Scooter Controller?

A 60V electric scooter controller manages the power flow from the battery to the motor.

How To Identify Controller Wires?

Check the wiring diagram for labeled colors and connections.

What Does A Wiring Diagram Show?

A wiring diagram displays connections between the controller, battery, motor, and other components.

Why Use A Wiring Diagram?

A wiring diagram ensures correct and safe connections.

How To Connect The Battery?

Connect the battery wires to the controller’s power input terminals.

What Are Throttle Wires?

Throttle wires connect the throttle to the controller, managing speed.

Conclusion

Understanding the 60V electric scooter controller wiring diagram ensures optimal performance. Proper connections enhance safety and efficiency. Take your time to follow the diagram accurately. This will help avoid potential issues. Enjoy a smooth and reliable ride with your electric scooter.

Happy riding!